🍁CANADA’S COMPOSITE EXPERT

LIGHTER.

FASTER. STRONGER.

Innovative Composite Solutions for

Sea, Air, Space, and Defense Industries

Why Choose PCI for High-Performance Composites?

Industry Leader in high-performance composite engineering and manufacturing.

Cutting-Edge Solutions designed for the most demanding industries.

Expertise in Precision Composites with advanced manufacturing techniques.

Rigorous Quality Control to ensure superior performance and reliability.

Customized Solutions that enhance efficiency, endurance, and structural integrity.

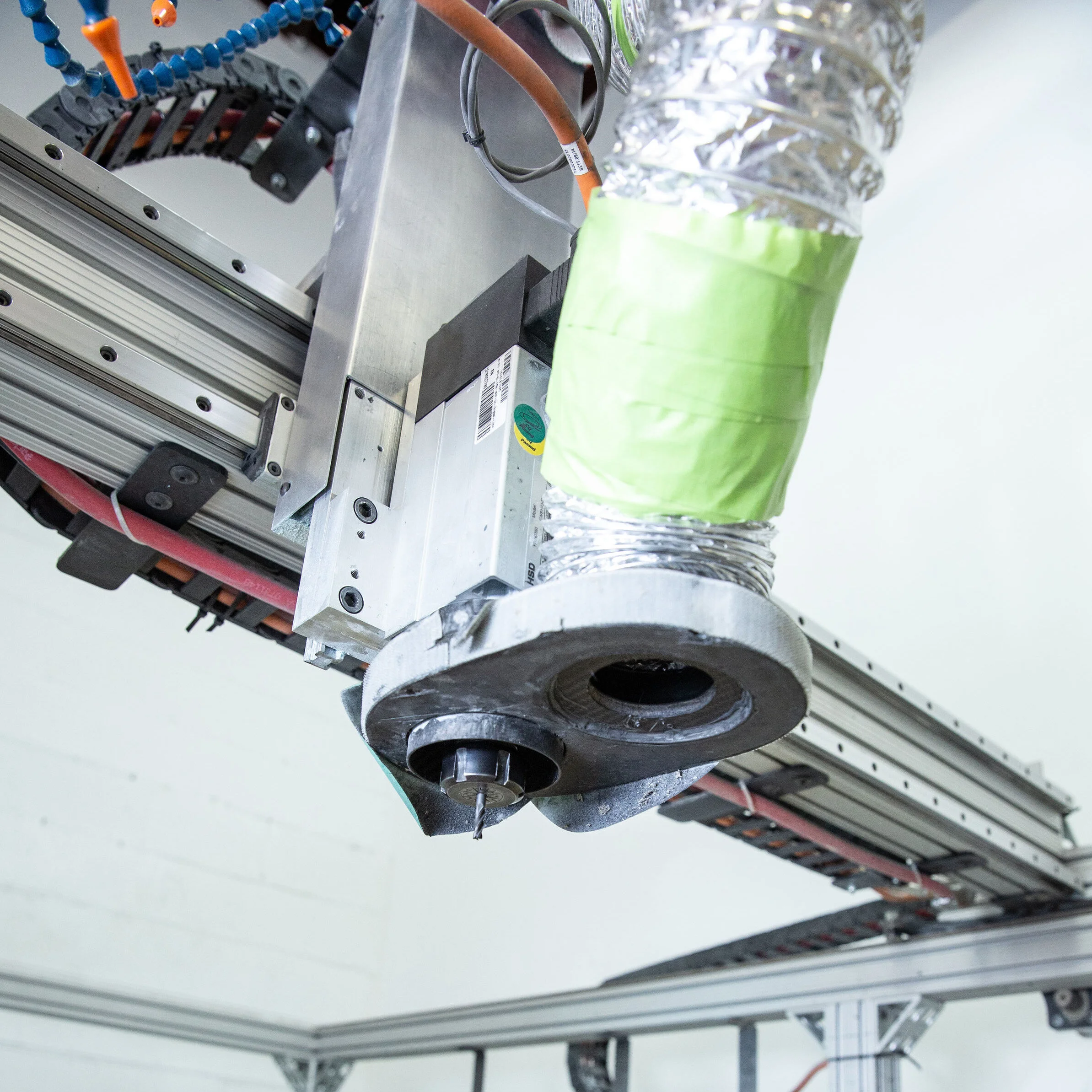

A Full In-House

Suite of Proprietary Equipment

allowing increased efficiencies and decreased lead times for all of our clients’ custom composite fabrication needs.